Thank you for Subscribing to Auto Business Outlook Weekly Brief

Auto Business Outlook: Specials Magazine

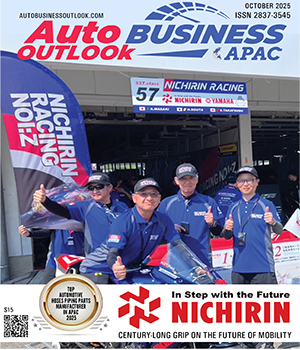

On any given morning in Kobe, Japan, Nichirin’s headquarters hum with the quiet precision of a company that has made engineering excellence routine, extending across 15 factories in 10 countries. It’s a scene that reflects both discipline and reach. Founded in 1914, Nichirin has evolved from a domestic hose manufacturer into a global leader in automotive hoses and piping systems. It supplies the lifelines inside motorcycles, passenger cars, commercial vehicles, and even household appliances. These are parts that are usually hidden but play a big role in performance, safety and comfort. Nichirin’s path has been shaped by a deliberate balance of global scale and local grip. It has mastered the ability to serve diverse markets with uniform quality while tailoring products to the specific needs, tastes and regulations of each region. This dual focus set the stage for its international journey. Overseas expansion began in the 1980s when it launched local production in North America. By the late 1990s, it had factories in mainland China and ASEAN (Thailand). In the early 2000s, it planted roots in Europe. Each move was focused on proximity to customers and their distinct requirements. “We’ve grown by establishing local production around the world,” says Hiroyuki Soga, president and CEO. “It’s not just about exporting parts but about embedding ourselves in each region’s needs, regulations and culture.” This decentralized yet coordinated footprint allows Nichirin to provide various products of uniform quality at competitive prices on a global scale. It also gives the company unusual agility when markets change, whether it is due to consumer preferences, safety regulations, or technological shifts. Customization as Core DNA Nichirin’s approach to product development is grounded in customization. In North America, for example, the motorcycle market demands durability and aesthetics. Nichirin designed brake hoses that deliver both a sleek appearance matched with high durability while complying with FMVSS standards. In Europe, regulatory change created a different kind of challenge. When the EU mandated ABS systems for motorcycles in 2016, Nichirin was prepared with a compliant hose design. At the time, it was a pioneering company in the industry that initiated development at an early stage. The result was a quick surge in sales and a strengthened reputation for technical agility. It is this ability to make small but crucial adjustments that align with how a product feels in use—what riders call “brake feeling”—that Nichirin has learned to deliver with precision.

Golf Electric Vehicle

Evolution Electric Vehicles leads the charge in electric golf cart innovation, drawing on nearly two decades of industry expertise. Jonathan Chun, the social media marketing coordinator at Evolution, emphasizes, “Experience is invaluable—it’s earned over time. While newcomers navigate their learning curves, we stand firm on our legacy of success in the industry.” Striking a balance between quality and affordability, Evolution makes modern, eco-friendly transportation accessible to a broader audience. While many competitors focus on higher-priced models with limited features, Evolution aims to democratize access to quality lithium-battery golf carts by offering industry-leading features at the lowest prices in the market. Revolutionizing the Golf Cart Industry Evolution has quickly risen to the top of the electric golf cart industry by consistently embracing innovation and incorporating features typically found in automobiles into golf carts. Evolution was the first to introduce a touchscreen interface in a golf cart—an innovation that set a new standard in the industry. Evolution also became the first golf cart company to standardize lithium batteries across all models. Unlike traditional lead-acid batteries, which require regular maintenance and are prone to issues, lithium batteries offer enhanced reliability and longevity with minimal upkeep, all at a lower price. Arguably, Evolution’s most significant achievement was the introduction of the D5 Series, which has swiftly become the company’s flagship model. Boasting innovative features such as a 9-inch multi-function touchscreen, a sound bar, and a first-ofits-kind adjustable steering column, the D5 redefined consumers’ preconceived notions about golf carts. “Our name, Evolution, embodies the ethos of pushing the boundaries of what a golf cart can be,” notes Chun. The D5 series revolutionized consumer preferences by offering forward-facing seats, a shift from the traditional flip-flop rear kit seats. For those who prefer the traditional seating configuration, Evolution continues to offer D5 models with this arrangement, providing customers with the options they desire.

Autonomous Vehicle Solution

The future of transportation is here, and it’s autonomous. Aurora Innovation is leading the way, transforming how people and goods move. It is developing selfdriving technologies that promise to make roads safer, transportation more efficient and the world more sustainable. “We are on the brink of a new era in mobility and logistics, and the excitement from the industry, our partners and customers is palpable,” said Chris Urmson, co-founder and CEO. In a world where traffic fatalities are far too common, and transportation inefficiencies are increasing, Aurora’s technology is poised to change the transportation landscape. Its vision goes far beyond creating self-driving cars, aiming to create a fully integrated ecosystem of autonomous vehicles that can navigate the roadways, freight corridors and urban streets safely and autonomously, without human intervention. The technology promises to reduce traffic accidents, improve efficiency and lower fuel consumption and emissions, paving the way for a safer, more sustainable and accessible transportation future. Advancing Autonomous Technology Founded by Chris Urmson, Sterling Anderson and James Andrew Bagnell, three experts with years of experience in the autonomous systems industry, Aurora has established itself as a major player in the race to develop autonomous vehicles. At the heart of Aurora’s technology is the Aurora Driver, a sophisticated autonomous system that enables vehicles to perceive, reason and drive safely in various environments. Two essential components—hardware and software— power the Aurora Driver to enable full autonomy. The hardware is engineered to provide precise and reliable perception of the surrounding environment. The system integrates Aurora’s FirstLight Lidar, which allows vehicles to see far ahead with unparalleled precision, detecting objects even at high speeds and in low-light conditions. High-performance cameras and radar work in tandem to provide a complete 360-degree view of the environment, ensuring the vehicle can detect and respond to obstacles, pedestrians and other road users. The computing system processes vast amounts of data in real time, allowing for split-second decision-making that enhances safety and efficiency. Designed with fail-safe mechanisms, Aurora’s hardware ensures continued operation even in the event of individual sensor failures, making the system resilient and dependable. Complementing the advanced hardware is a software stack designed to handle the complexities of autonomous navigation. The software interprets sensor data to recognize objects, anticipate their movements and predict potential hazards on the road. Using advanced AI and machine learning, the Aurora Driver calculates the safest and most efficient driving decisions in real time, ensuring smooth and predictable maneuvers. Aurora’s high-definition maps enable precise navigation, allowing autonomous vehicles to operate accurately in complex environments. The company continuously refines its technology through extensive testing—using real-world public roads and simulated environments—to improve decision-making in rare and challenging scenarios.

CXO INSIGHTS

Evolutions in the Auto Tech Industry

Nick Rumberger, Executive Director, Engineering & Sales, BILSTEIN

Artificial Intelligence and Automotive Engineering: Generative Design and the AI-Defined Vehicle

Brendan J. Chan, Ph.D., Sr. Chief Engineer – Autonomy and Active Safety, Oshkosh Corporation [NYSE: OSK]

Lean Manufacturing Excellence

Terrence H. Slaughter, Plant Production Manager, Toyota North America

Aiming for an Energy-Efficient World

Trent Randles, Engineering Manager, BorgWarner [NYSE: BWA]

Evolving Manufacturing: The Strategic Role of Industrial Fastener Distribution

Blake Ritter, Branded Products Segment Manager, Lincoln Industries

From Robots to Results: Scaling Manufacturing with People in Mind

Michael Spliedt, Senior Engineering Manager, Yanfeng

Long-Standing Lean Thinking

Stewart Johnstone, Vice President Asia, Adient

IN FOCUS

Transforming Mobility: The APAC Auto Parts Manufacturing Landscape

Auto parts manufacturing in the APAC region strengthens global automotive supply chains, fostering innovation, cost efficiency, and sustainability while meeting rising mobility demands.

Smart Manufacturing: AI's Influence on APAC Automotive Hose and Piping Production

APAC automotive hose and piping manufacturers are adopting AI to enhance efficiency, quality, and sustainability, driven by EV demand, stringent regulations, and the need for advanced manufacturing capabilities.

EDITORIAL

Advancing Hose and Piping Manufacturing Excellence

This transformation is redefining how OEMs select partners. Material science expertise, system integration capabilities, and compliance with increasingly strict regional standards are now key differentiators. To stay competitive, APAC suppliers are investing in advanced elastomers, automated production systems, and localized R&D facilities to deliver higher performance while meeting environmental commitments.

The transition to electric and hybrid vehicles is one of the strongest drivers of change. Thermal management has become essential, as batteries, inverters, and high-voltage systems require precise temperature control. Hose and piping manufacturers are designing assemblies that tolerate higher pressures, offer enhanced flexibility, and remain compatible with next-generation coolants. China, Japan, and South Korea currently lead in this segment, with India and Southeast Asia scaling rapidly to serve domestic and global markets.

Material innovation further reshapes the sector. Silicone and thermoplastic elastomers are supplementing traditional EPDM, providing superior resistance to heat and chemicals. OEMs are also pushing for recycled and bio-based feedstocks, positioning sustainable materials as a competitive edge in meeting automakers’ carbon-reduction goals. Beyond cost efficiency, suppliers are differentiating themselves through value-added engineering, embedding sensors for predictive maintenance, developing modular systems for simplified assembly, and adopting automated inspection for consistent quality.

This edition highlights the expert perspectives of David Chia, Managing Director at Beckhoff Automation, and Michael Cavaretta, Analytics Executive - Quality Analytics, Ford Motor Company. These esteemed professionals share their invaluable insights on the developments and challenges within the sector, along with possible solutions.

We hope these valuable insights from industry leaders featured in this edition will assist you in making informed decisions for your businesses.